About Belt Conveyor

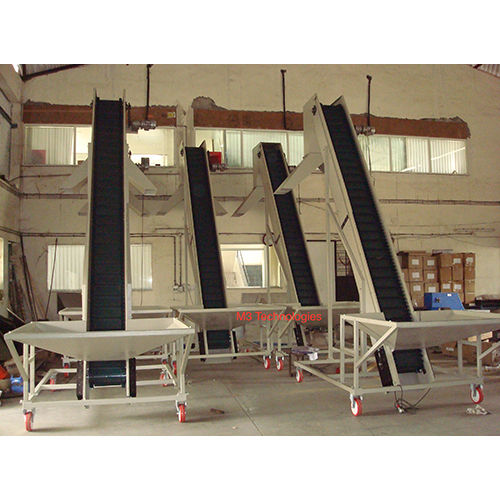

Belt Conveyor is one of the most commonly used conveyor systems inmanufacturing and other industrial applications. It uses a continuous belt totransport materials or products from one place to another. The belt is moved bya motor-driven pulley that rotates the belt, which in turn moves the materialalong the belt. It is manufactured at our advanced manufacturing unit using topgrade raw material and progressive technology in synchronisationwith definedindustrial norms. It is highly admired for its optimum quality and longerlife. Further, the offered range of Belt Conveyor can be purchasedfrom us at reasonable price.

Product Details:

- SizeDifferent Sizes Available

- UsageIndustrial

- MaterialStainless Steel

- Belt ConveyorFlat Belt

- Resistant FeatureHeat Resistant

Versatile Industrial SolutionEngineered from high-quality stainless steel, our flat belt conveyors offer unmatched versatility in industrial settings. Their design accommodates a range of applications, from assembly lines to heat-intensive environments. The customizable sizes ensure seamless integration into existing workflows, while the heat-resistant feature allows continuous operation even under demanding temperatures.

Reliable Performance & CustomizationOur belt conveyors stand out for their consistent, reliable operation. The flat belt design supports a variety of transported goods, while the robust materials prolong service life. We offer tailored manufacturing and supply options throughout India, ensuring every customer receives a conveyor system that perfectly matches their business needs and operational conditions.

FAQs of Belt Conveyor:

Q: How is a stainless steel flat belt conveyor installed and maintained in industrial environments?

A: Installation involves securing the conveyor frame, aligning and tensioning the flat belt, then connecting the power and control systems. Regular maintenance includes inspection for wear, cleaning to prevent residue buildup, and periodic lubrication of moving parts, ensuring optimal performance and durability in industrial settings.

Q: What are the benefits of using a heat-resistant, stainless steel flat belt conveyor?

A: The heat-resistant stainless steel construction ensures that the conveyor can handle high-temperature processes without damage or performance degradation. This enhances safety, extends the lifespan of the equipment, and enables smooth handling of heated materials in industrial applications.

Q: When should a business consider upgrading to an industrial flat belt conveyor?

A: A business should consider upgrading when handling volumes increase, working conditions require robust and heat-resistant equipment, or when automation and efficiency become operational priorities. Upgrading to stainless steel flat belt conveyors minimises downtime and supports scalable growth.

Q: Where are these belt conveyors typically used within industrial operations?

A: These conveyors are widely used in manufacturing plants, food processing units, packaging facilities, and assembly linesanywhere efficient, heat-resistant material transport is essential. Their flexibility in size makes them suitable for various layouts and process requirements.

Q: What processes are supported by using this flat belt conveyor system?

A: This conveyor efficiently manages processes such as material transfer, assembly, inspection, and packaging. Its heat-resistance makes it suitable for processes involving hot items, maintaining productivity and safety without compromising material or operational integrity.

Q: How does the customization process work for selecting the right belt conveyor size and features?

A: Customers can consult with us to share their specific operational requirements. Based on application, load, and space constraints, we recommend suitable conveyor sizes and belt specifications, ensuring a tailored solution for maximum efficiency and integration.

Q: What usage precautions should be followed for optimal conveyor performance?

A: Operators should ensure regular inspection, proper loading within specified limits, and avoid using the conveyor for materials exceeding its heat resistance. Following manufacturer guidelines for cleaning and maintenance further promises reliable performance and safety.